What are the calibration services we offer?

Calibration of equipment is a vital process to ensure its performance, efficiency and safety. Over time, all measuring equipment loses accuracy, which leads to a condition called “measurement error”. These errors can cause the equipment to deviate from the standards and lead to inaccurate results. Periodic calibration eliminates this problem and ensures that the equipment operates accurately and reliably. Therefore, organizations must strictly adhere to international calibration standards when calibrating equipment.

- Calibration of pressure, flow and volume measuring instruments

- Calibration of temperature measuring instruments

- Calibration of electrical measuring instruments

- Calibration of physicochemical measuring instruments

- Calibration of mass measuring instruments

- Calibration of mechanical and geometric measuring instruments

Calibration of pressure, flow and volume measuring instruments

The correct operation of pressure and flow measuring devices is essential for the stability and safety of industrial processes. Calibration ensures accurate pressure measurement and prevents possible malfunctions. Calibration of pressure sensors is essential for the safe operation of equipment. Let’s list the importance of calibrating pressure measuring devices:

- Accuracy: The accurate measurement provided by pressure sensors increases the safety and stability of industrial processes.

- Safety: Accurate pressure readings prevent overloading or malfunctions in systems.

- Compliance: Meets international regulatory standards for pressure-based equipment such as boilers, pumps, and pipelines.

- Cost savings: Early detection of pressure problems prevents serious equipment damage and additional repair costs.

Calibration of temperature measuring instruments

Temperature measuring devices play a critical role, especially in laboratory and production processes. Calibration ensures that the devices operate correctly. An example is the accurate measurement of temperature sensors. What are the benefits of calibrating temperature measuring devices?

- Accuracy: Accurate temperature measurements ensure the stability and quality of production processes.

- Compliance: Ensures compliance with sanitary and safety regulations in the food production and pharmaceutical industries.

- Safety: Minimizes the risk of fire hazards and equipment overheating.

- Efficiency: Reduces energy consumption by supporting process optimization.

Calibration of electrical measuring instruments

Incorrect measurement of electrical devices can cause serious economic and safety problems. Calibration minimizes these risks and ensures that the equipment operates properly. For example, calibration of electrical voltage measuring devices can prevent overloading in the power distribution system. The importance of calibrating electrical measuring devices is as follows:

- Accuracy: Ensures the reliability of power systems by increasing the accuracy of electrical voltage and current measurements.

- Safety: Prevents electrical faults and short circuits.

- Compliance: Meets the requirements of regulatory bodies and industry standards.

- Cost savings: Reduces costs and supports system optimization with accurate calculation of energy consumption

Calibration of physicochemical measuring instruments

The accuracy of chemical analysis devices directly affects the quality of laboratory results. Calibration ensures the reliability of these devices. For example, it ensures the proper functioning of devices and equipment used in laboratories and the reliability of analysis results. The importance of calibrating physicochemical measuring devices is as follows:

- Accuracy: The accurate operation of laboratory equipment increases the reliability of analysis results.

- Reliability: Ensures that chemical analysis results comply with international standards, especially in the pharmaceutical and food industries.

- Compliance: Meets the quality standards required by regulatory authorities.

- Safety: Accurate analysis results prevent potential risks.

- Cost savings: Prevents material waste and makes processes more efficient by reducing errors during analysis.

Calibration of mass measuring instruments

Weighing devices are essential for accurate calculations in commercial and industrial settings. Calibration reduces the likelihood of inaccurate measurements. For example, the calibration of scales used in pharmaceutical manufacturing ensures accurate dosages. What are the benefits of calibrating mass measuring devices?

- Accuracy: The accurate operation of scales and weighing devices ensures the proper conduct of production and trade processes.

- Compliance: Calibration according to international and local standards guarantees product quality.

- Efficiency: Reduces material and product loss by preventing incorrect measurements.

- Safety: Minimizes the negative impact of excessive or incorrect weight measurements on operations.

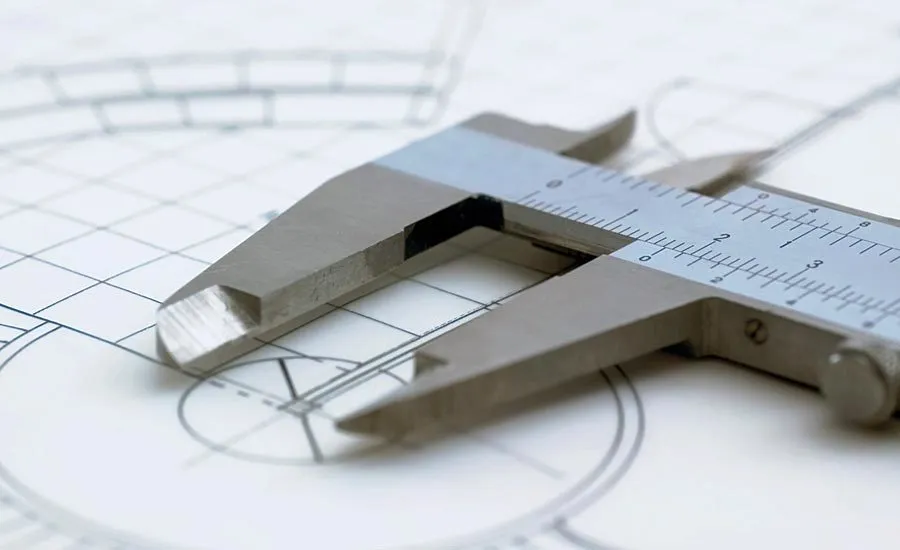

Calibration of mechanical and geometric measuring instruments

Calibration of mechanical measuring instruments is essential for the accurate execution of engineering projects. Calibration also helps to improve product quality. For example, proper calibration of external measuring instruments used in metalworking ensures that the product is manufactured exactly according to the design standards. What are the importance of calibrating mechanical measuring instruments?

- Accuracy: Calibration of mechanical measuring devices ensures that the product is manufactured according to design standards.

- Safety: Any error in the size of moving and mechanical parts can cause equipment failure. Calibration eliminates these risks.

- Efficiency: Accurate measurements help optimize production processes and use materials efficiently.

- Compliance: Ensures compliance with the levels of accuracy required in engineering projects.

Maybo Calibration: Calibration Services

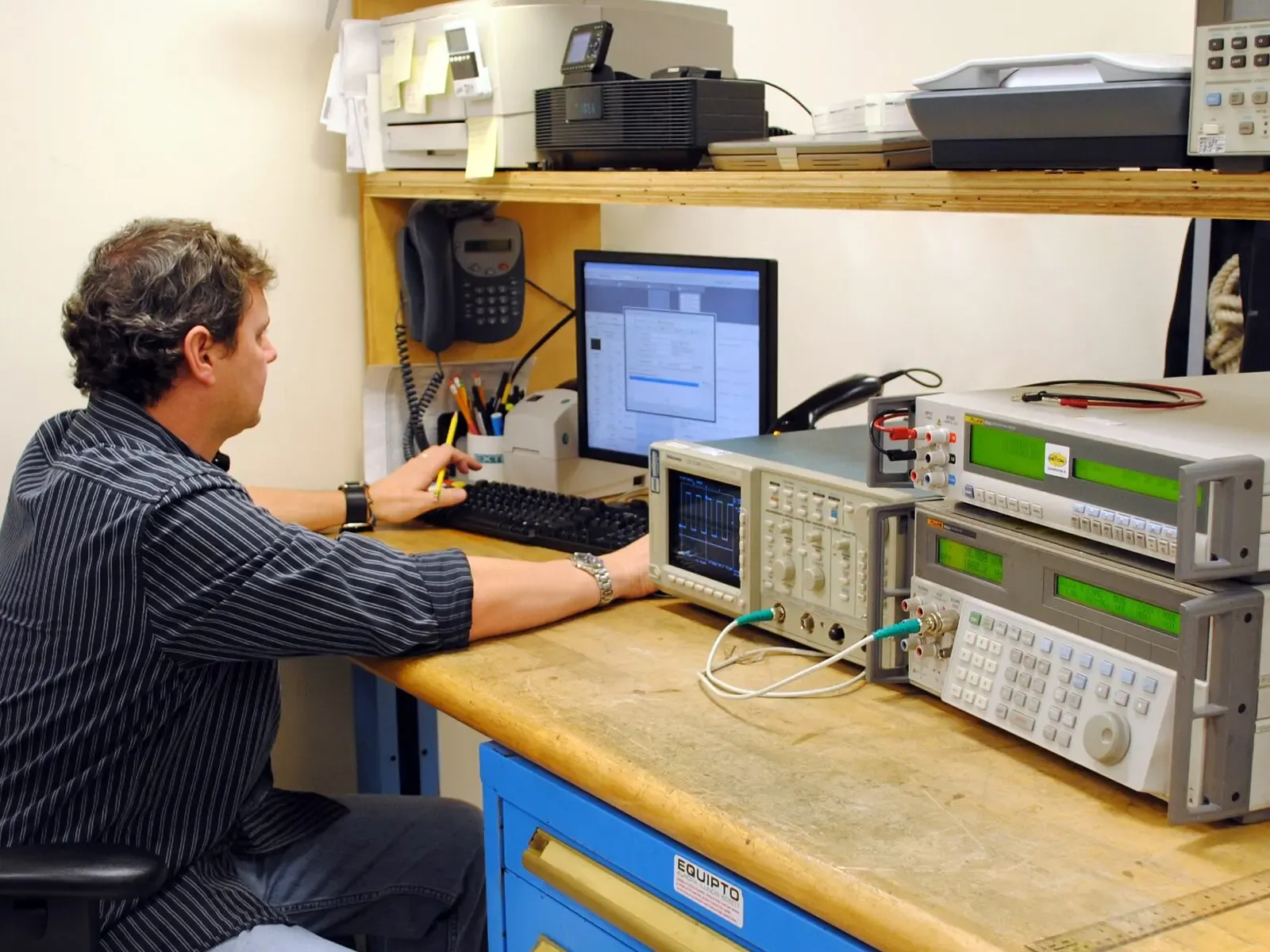

Maybo Calibration is a professional company operating in accordance with ISO 9001:2015 and ISO/IEC 17025:2020 standards, providing high-precision and reliable calibration services. We provide calibration in accordance with international standards and always prioritize quality to earn the trust of our customers.

Our engineers working in our calibration laboratory have extensive experience and provide services tailored to the specific requirements of various industries. Our laboratories, equipped with high-tech equipment, ensure that calibration processes achieve accuracy. Our services allow you to ensure optimal performance of your equipment, increase the efficiency of your production processes and strengthen the reliability of your tests.

At Maybo Calibration, we provide services that are fully compliant with international standards, while also meeting the requirements of industry and regulatory authorities. We apply best practices in quality management under the ISO 9001:2015 standard, and we certify laboratory competence and accuracy of calibration processes under the ISO/IEC 17025:2020 standard.